-

Volumes 96-107 (2025)

-

Volume 106

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 106

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

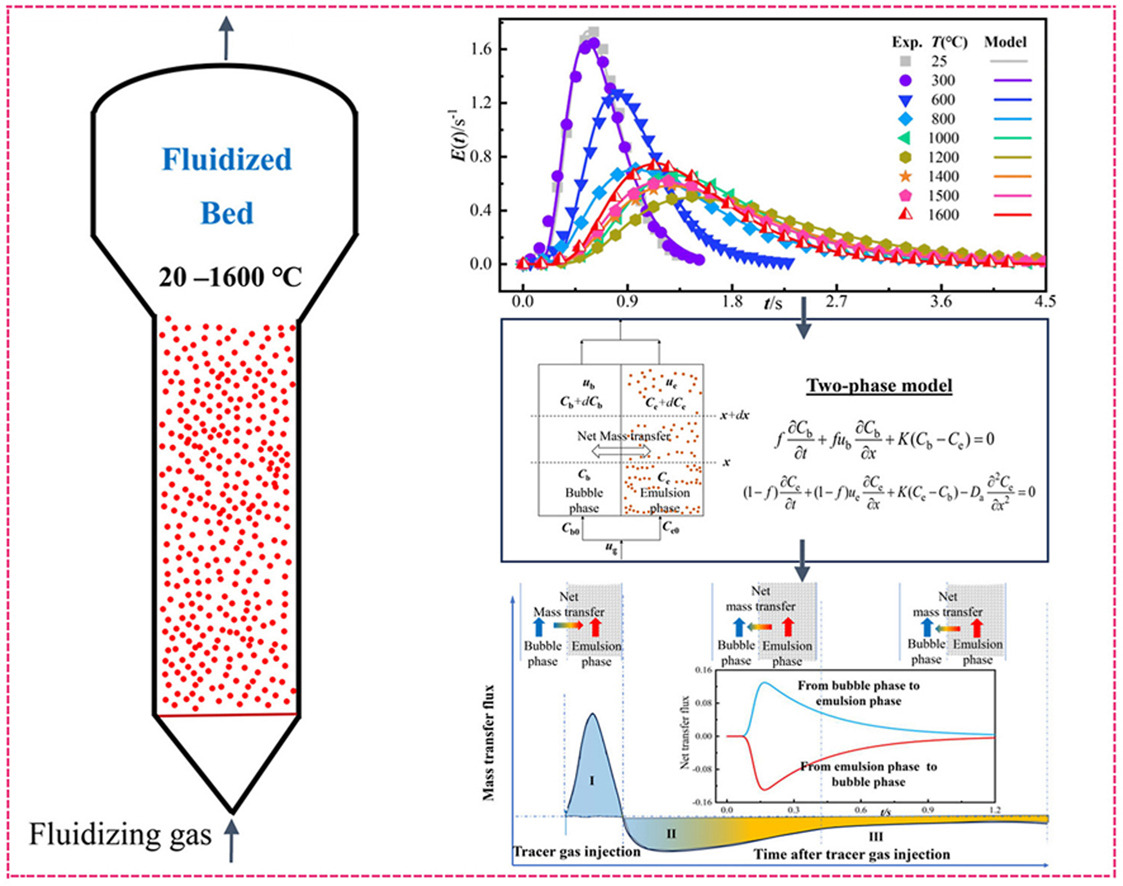

• The two-phase model can quantify mass transfer coefficients (K) from gas residence time distributions.

• The K peaks between 300 and 800 °C and stabilizes above 1200 °C.

• Mass transfer flux between the two phases reduces with superficial gas velocity.

• Static bed height and particle size affect the variation of K with temperature.

Understanding interphase mass transfer is crucial for the efficient design and operation of gas–solid fluidized beds, which are widely used in various industrial processes. However, research on mass transfer behavior in such systems, particularly at high temperatures (e.g., >1000 °C), remains sparse. This study, dedicated to Profs. Yong Jin and Zhiqing Yu's contributions to fluidization, elucidates the mass transfer behavior of gas-solid bubbling fluidized beds at temperatures up to 1600 °C by modeling gas residence time distribution data using a two-phase model. We examine the effects of temperature, gas velocity, bed height, and particle size on mass transfer characteristics. The results reveal that the mass transfer flux increases with temperature up to 800 °C, peaking within this range before stabilizing above 1200 °C. This trend is closely linked to the behavior of bubble dynamics, where bubble size initially decreases significantly as temperature rises, eventually reaching a plateau at higher temperatures. Experimental pressure fluctuation analysis validates this behavior, further supporting the observed temperature effects on bubble dynamics. Higher gas velocity reduces the mass transfer flux and mitigates back-mixing, while bed height and particle size affect bubble dynamics in a nonlinear manner. Experimental validation confirms the potential of these findings for optimizing the design and operation of high-temperature bubbling fluidized bed reactors.