- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

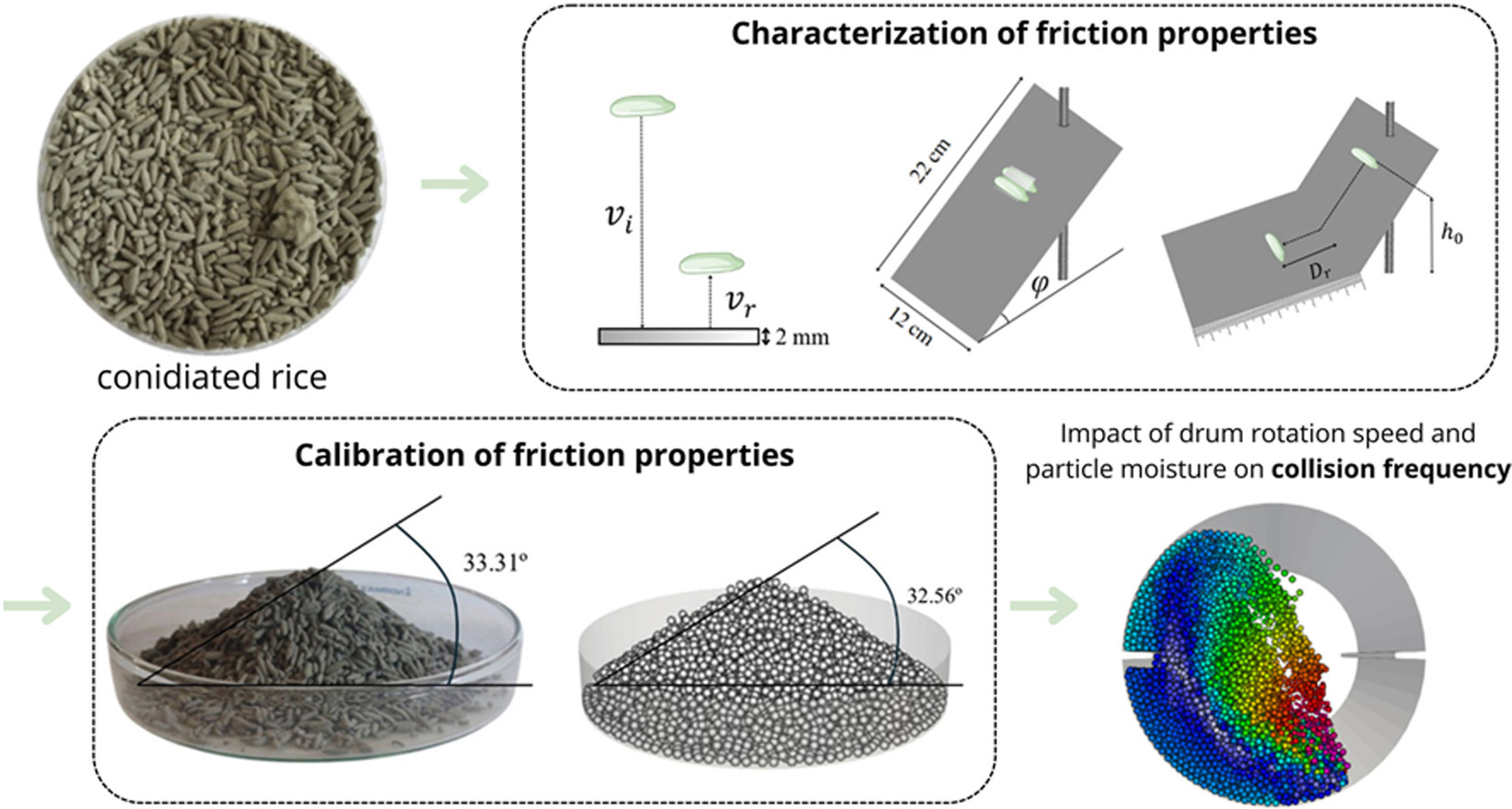

• Collisions during M. anisopliae spore extraction were studied using rotating drums and DEM simulations.

• Moisture content and drum rotation speed were evaluated as key variables in particle behavior.

• Frictional properties for particle–particle and particle–wall contacts were measured at varied moisture levels.

• Lower moisture altered friction, drum fill dynamics, and the frequency and intensity of particle collisions.

• Higher forces occurred at 60 rpm, yet the effective impact frequency remained comparable to that at 30 rpm.

The fungus Metarhizium anisopliae is commonly cultivated on rice, and the extraction of its spores remains a critical step with room for optimization in biofactories. Rotary drums are emerging as a promising technology. This study evaluated the effect of drum rotation speed (30 and 60 rpm) and particle moisture content (0.250; 0.111; and 0.053 kg-w/kg-ds) on the collision forces and frequencies of rice particles during the extraction process. To this end, the Discrete Element Method (DEM) was applied to simulate particle motion and collisions. The simulations were carried out using a rotary drum with a diameter of 20 cm and a length of 33 cm, equipped with two straight lifters. Spherical particles with structural and material properties referring to conidiated rice particles of different moisture contents were used. The DEM input parameters, restitution as well as static and rolling friction coefficients for particle-particle and particle-wall contacts, were experimentally determined. The experiments indicated that the moisture content of the particles predominantly affects the sliding friction coefficient, while the softness resulting from the cooking of the rice mainly influences the coefficient of restitution. The rolling friction coefficient, in turn, was primarily impacted by the sphericity of the particles. Additionally, the reduction in moisture content, by decreasing the drum's filling degree, promoted the expansion of the active layer, the region associated with more intense particle collisions. The results indicated that, despite the higher collision velocities observed at 60 rpm, the frequency of impacts with sufficient energy to overcome adhesive forces did not significantly increase compared to the 30 rpm condition. As a major outcome, DEM simulations clearly revealed that the reduction of particle size, associated with decreasing moisture content, resulted in a considerable drop of the filling degree, yielding an expansion of the active layer and therefore enhanced particle mobility. This is an important finding with great interest for the scale-up of continuous spore extraction in rotary drums.