- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

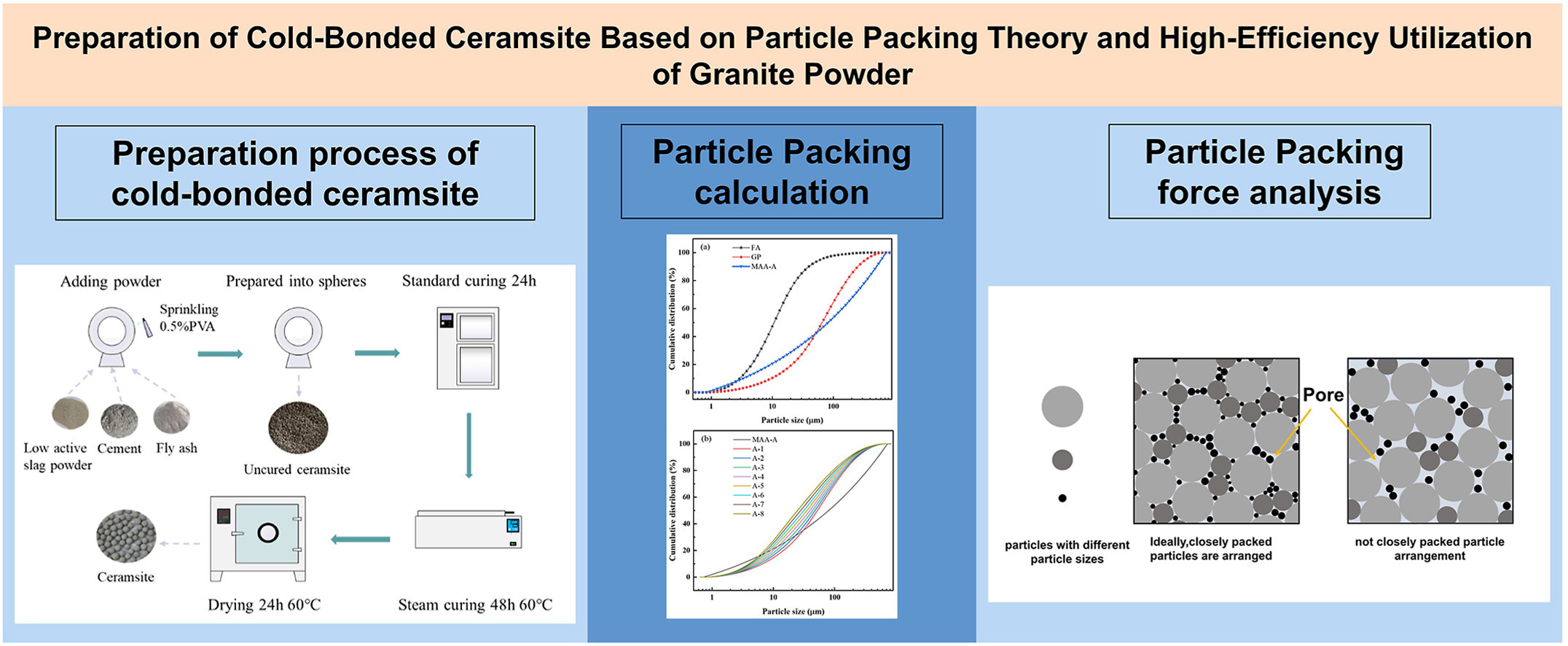

• MAA packing-curve design controls pellet porosity and strength.

• Lower RSS (better PSD fit) increases densities and reduces water uptake.

• Best window: bulk 1041 kg/m3, apparent 1669 kg/m3, water 11.86 %.

• Single-pellet crushing strength up to 5.76 MPa at optimal packing.

• Full PSD outperforms mono-sized blends in strength and absorption.

The utilization of granite powder (GP) is substantially limited by its low pozzolanic activity and inert structure, posing a significant challenge for its high-volume incorporation. This study conducts experimental research on cold-bonded ceramsite based on the GP–fly ash–cement system, adopting the modified Andreasen–Andersen (MAA) particle packing model as a tool for mix ratio design and evaluation. By designing multiple groups of different particle size combinations, the raw material particle gradation is made to produce controllable deviations from the MAA target curve within a certain range. RSS is used to quantitatively characterize the degree of deviation of the particle gradation from the MAA target curve, and the influence mechanism of this deviation on the physical properties and pore structure of ceramsite is systematically analyzed. The results indicated that an RSS value of 6736 yielded the most compact ceramsite structure, which exhibited a cylinder compressive strength of 5.76 MPa, a bulk density of 1041 kg/m3, and a water absorption as low as 12.65 %. Further particle size fractionation experiments revealed that single-size raw material systems performed significantly worse than full-range particle distributions. The latter facilitated the formation of a skeleton–filler collaborative structure, thereby enhancing compactness and mechanical stability. Compared with existing utilization pathways of GP, the proposed structure-regulated preparation strategy for cold-bonded ceramsite enables up to 85 % incorporation of GP and delivers comprehensive performance improvement without reliance on high-temperature sintering or alkali activation. This approach demonstrates considerable engineering feasibility and application potential, providing a novel perspective and theoretical foundation for the high-efficiency valorization of low-activity solid wastes.