- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

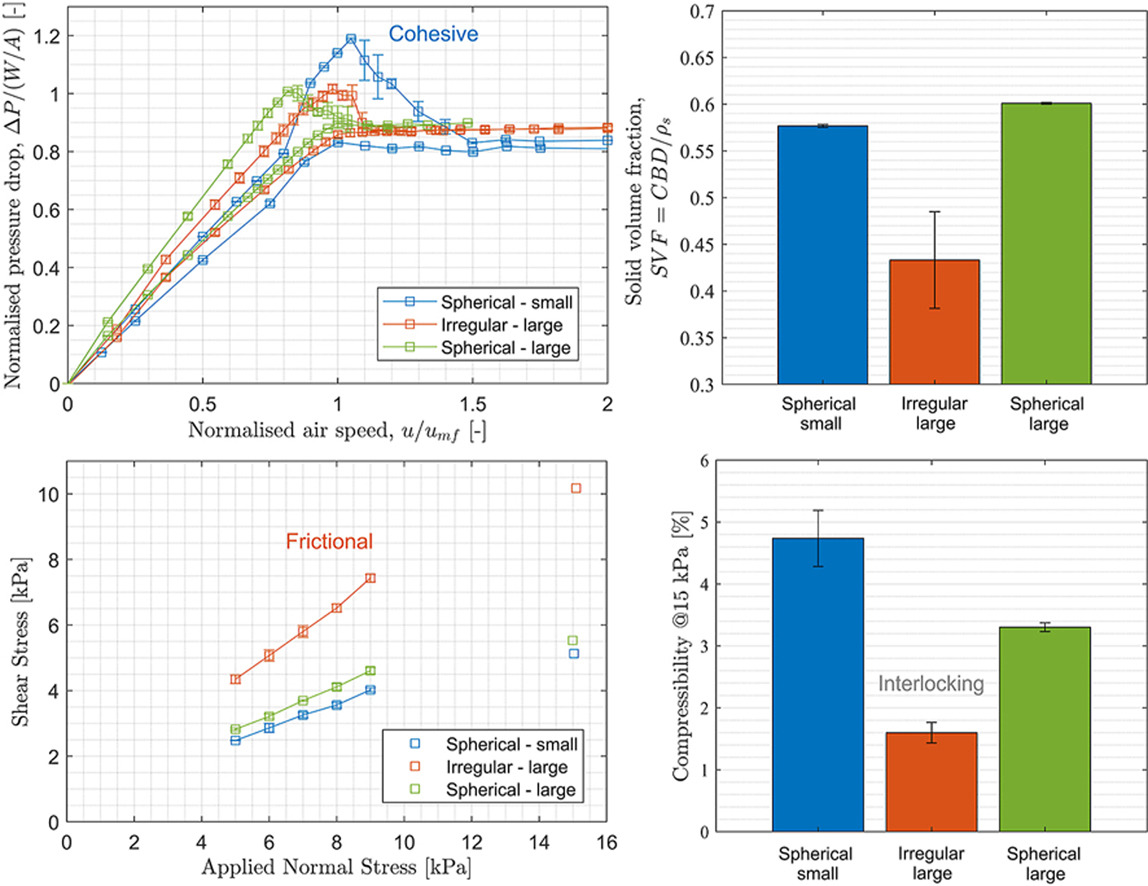

• Identification of the rheological tests where cohesion and friction are most likely to dominate.

• We propose the best experimental descriptors of exclusively cohesive or frictional effects.

• Successful differentiation supports comprehensive flow characterisation in any stress regime.

• The protocol is applied to commonly used powders across pharma,AM,food,and other industries.

• The method allows for direct comparison of flowability between different materials.

Powder flow behaviour is the result of countless combinations of interparticle forces of different natures: frictional, interlocking, cohesive and adhesive forces. We identify the rheological tests where one mechanism is most likely to dominate over the rest, and we propose the best descriptors of uniquely cohesive or frictional effects. We describe the procedure for a fluidisation test and the features of the results linked to powder cohesivity. We contrast these features against shear test results to determine powder frictional properties, explaining the conditions and limitations of the analysis. We use solid volume fraction and compressibility measurements to assess the extent to which the different mechanisms influence natural packing and forced flow in intermediate stress regimes. The proposed experimental protocol and framework of interpretation is applied to a wide range of powdered materials, representing typical industrial issues. The qualities of the characterisation are discussed and compared to those associated with traditional rheological testing methods. The framework successfully differentiates the effects of the various interparticle interaction mechanisms on powder flow,enabling a comprehensive prediction of powder behaviour in a variety of handling and processing settings. The metrics used are all normalised,allowing for a universal direct comparison of flowability across completely different materials.