-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

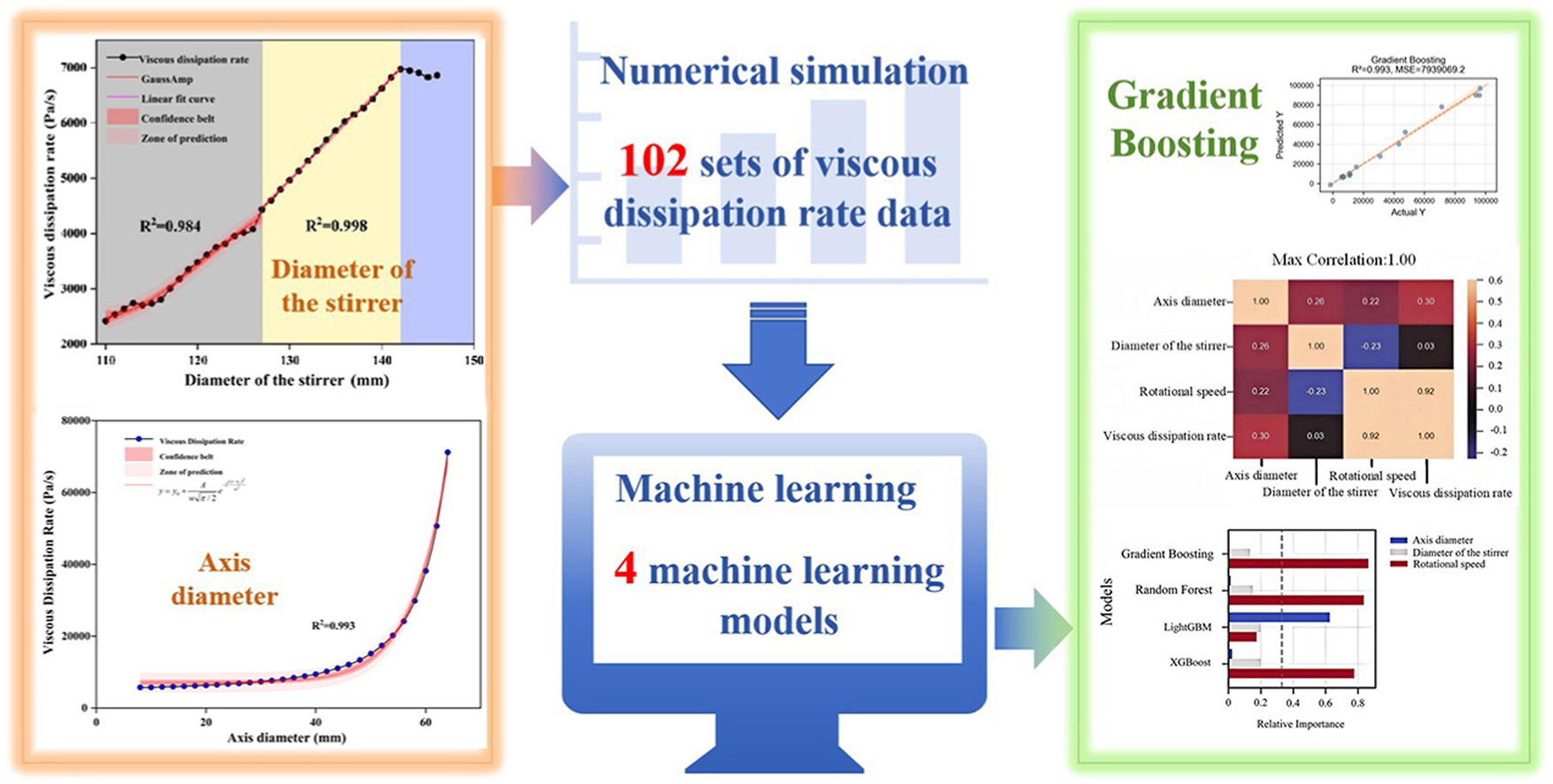

• Reveal different nonlinear influence laws of geometric parameters of agitator on grinding effect.

• Discover importance of variable group size to the fitting accuracy of geometric parameters.

• Analyze multi-factor coupling mechanism and weight ranking based on fusion of machine learning and numerical simulation.

• Determine gradient boosting model as optimal model for predicting viscous dissipation rate and propose engineering guidance.

The rod and pin stirred mill is a key device for micron-sized powder production, yet the quantitative understanding of its grinding mechanism under multi-parameter coupling remains insufficient. This study develops a coupled flow field model based on computational fluid dynamic to investigate how agitator diameter, shaft diameter, and rotational speed influence viscous dissipation. Results reveal a positive correlation between these parameters and viscous dissipation rate, following a power-law relationship. Specifically, the agitator diameter shows a two-stage linear effect, while the shaft diameter exhibits Gaussian-type nonlinear growth. Numerical simulation combined with machine learning enables sensitivity analysis, indicating that rotational speed has the most significant impact, followed by shaft diameter and agitator diameter. The Gradient Boosting model demonstrates the highest prediction accuracy. These findings provide a quantitative basis for the engineering design of high-performance stirred mills.