- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

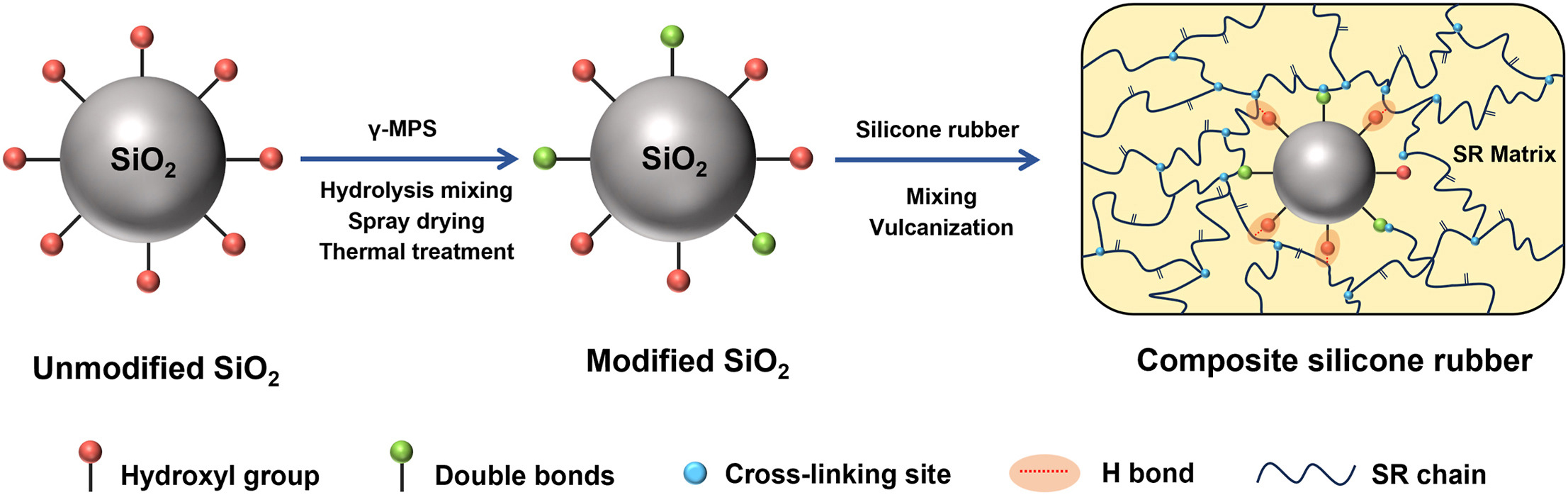

• Developed a modification route combining hydrolysis, spray drying, and heating.

• Grafted double bonds react with SR side chains forming cross-links network.

• Optimal SiO2 dispersion and SR tensile strength obtained through γ-MPS modification.

• Excess γ-MPS caused agglomeration and multilayer grafting, reducing strength.

The reinforcing of silicone rubber using nano-SiO2 is currently constrained by the weak interfacial interactions dominated by hydrogen bonding and van der Waals forces between particles and the matrix. This limitation hinders the development of silicone rubbers with high-strength and high-transparency. In this study, a novel organic modification approach involving "hydrolysis mixing, spray drying, and thermal treatment" was developed to graft γ-(methacryloxypropyl)trimethoxysilane (γ-MPS), containing double-bonds, onto the surface of precipitated SiO2 particles. During curing, these surface-grafted double-bonds react with the double-bonds on the silicone rubber side chains, forming an interfacial cross-linking network between inorganic particles and the organic matrix. Experimental results show that composites incorporating SiO2 particles modified with 2 wt% γ-MPS adding exhibit the highest tensile strength of 9.47 MPa, attributed to the optimal particle dispersion and formation of interfacial cross-linked network. Particle dispersion which is quantified by a dispersion index reached the lowest values at 2 % γ-MPS, indicating the uniform dispersion. Consistently, curing rheology showed the maximum effective torque reaching 3.16 dN m at 2 %, reflecting the highest double bond interfacial cross-link density. Silicone rubber composites with 0.5 %–2 % γ-MPS modified particles exhibit optimal tensile strength and transparency. However, the increasing amount of γ-MPS leads to intensified condensation of hydrolyzed silane species, resulting in particle agglomeration and multilayer grafting on the particle surfaces, which adversely affects mechanical performance and transparency. To prepare high-strength and high-transparency silicone rubber, effective suppression of the condensation of silane coupling agent hydrolysis products and achievement of monolayer grafting on particle surfaces are necessary.