- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• SVM models achieved R2 up to 0.99 for accurate particle size distribution prediction.

• SEM analysis revealed morphological transitions during Al-B4C powder milling.

• Surface roughness increased to 0.39 nm,analyzed using SPIP™ and GPR models.

• Mid-sized B4C particles showed optimal reduction with balanced milling times.

• Increasing B4C content to 10 % improved SVM accuracy in capturing milling dynamics.

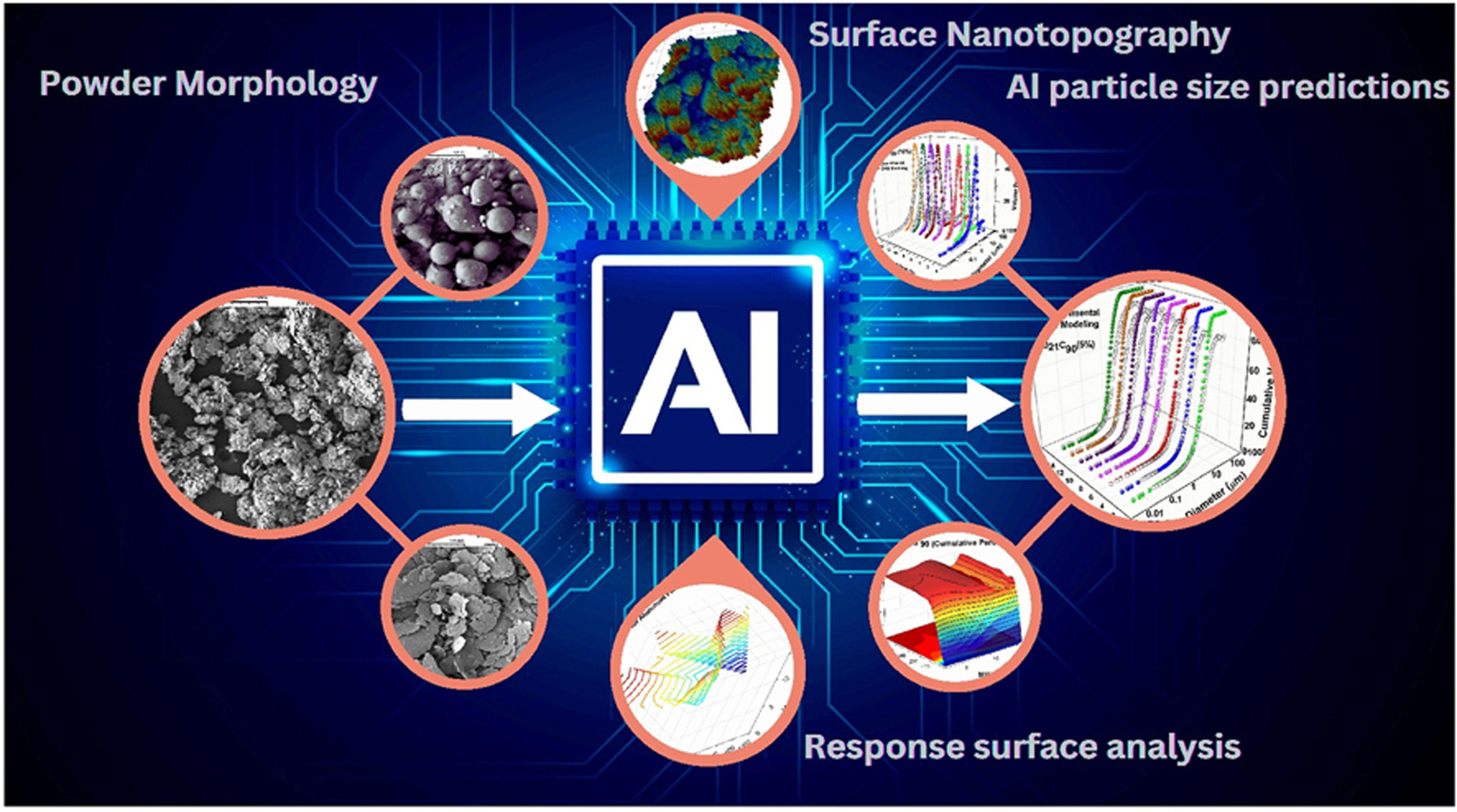

This study presents a machine learning-based approach using Support Vector Machines (SVM) to model the particle size distribution (PSD) and predict surface characteristics of Al-B4C nanocomposite powders synthesized through high-energy ball milling. Two SVM kernels, Polynomial and Radial Basis Function (RBF), were applied to simulate PSD curves and surface morphology, with experimental validation conducted via laser particle size analysis and scanning electron microscopy (SEM). The models demonstrated strong predictive capabilities, achieving R2 values between 0.91 and 0.99 and cross-validation coefficients (q2) from 0.93 to 0.99. Normal distribution models yielded lower RMSE values (0.11–2.13) compared to cumulative distribution models (4.34–6.55), indicating higher precision in modeling. SEM analysis revealed morphological transitions during milling, with particles evolving from spherical to fragmented shapes after 4 h. Surface metrics including roughness, waviness, and isotropy were quantified, showing that isotropy decreased from 82.48 % at 0 h to 57.69 % at 4 h due to directional deformation, then partially recovered to 62.50 % at 10 h. Gaussian Process Regression (GPR) showed strong alignment with experimental surface trends and accurately predicted nanoscale topographic parameters. Response Surface Methodology (RSM) was employed to visualize size reduction behavior for B4C particles with initial sizes of 90, 700, and 1200 nm. For 700 nm particles, size reduction stabilized beyond 10 h, while 90 nm particles exhibited rapid refinement within the first 5–10 h. In contrast, 1200 nm particles showed slower, continuous reduction requiring >15 h of milling. SVM models successfully captured these nonlinear trends,with minor underestimations at intermediate time points. RSM plots for aluminum particle sizes (21 and 71 μm) revealed that Al-21 led to stable and uniform distributions,whereas Al-71 exhibited nonlinear behavior with volume percentage drops under specific conditions. These findings confirm that SVM and GPR are robust tools for modeling PSD and surface evolution in ball-milled nanoparticles.