- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

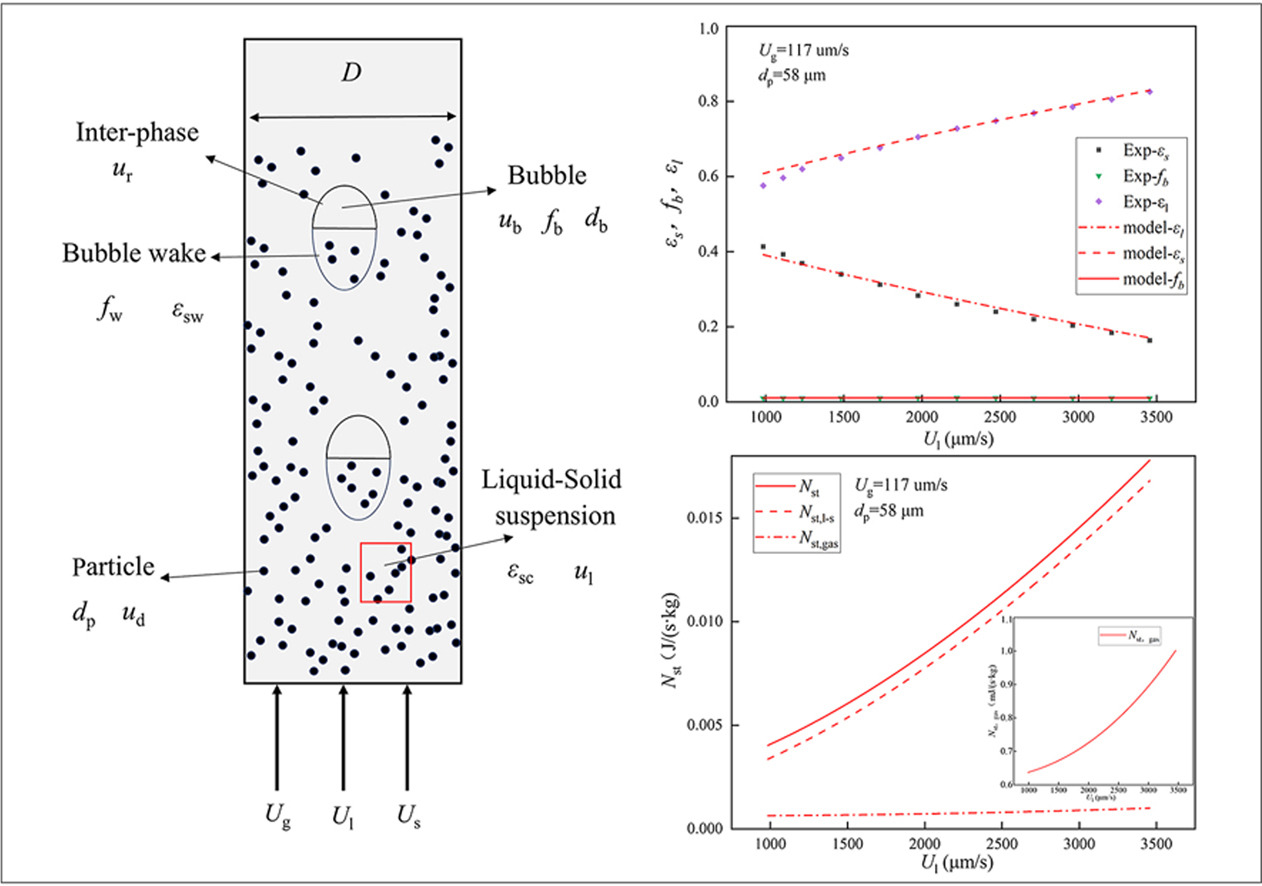

• Effect of wall on flow structure is firstly considered in meso-scale study.

• A new EMMS model for gas-liquid-solid micro-fluidized bed is proposed.

• Accuracy of the prediction for GLSMFB systems is improved.

Gas-liquid-solid mini-fluidized beds known for high efficiency with controllable mass and heat transfer characteristics, have good application prospects in fields such as multiphase reaction process enhancement and intrinsic kinetic detection. For three-phase mini-flow systems, the bed wall has a significant impact on spatiotemporal distribution of multi-phase flow structure, which influence the motion state of dispersed phase, make predicted phase holdup and residence time deviate from experimental values. However, current research on the quantitative impact of bed walls on flow structures is still limited, which hinders the optimization design and industrial application of such reactors. In this work, a meso-scale flow model of gas-liquid-solid mini-fluidized beds considering macro-scale effects between bed wall and flow is developed based on the principle of meso-scale science and introducing semi-theoretical formulas that take the effects of bed walls on particles and bubbles into account. The calculated values of this model are in good agreement with experimental data, where prediction of phase holdup fits well with experimental results, the deviation of bubble size and terminal velocity are within 10%. Compared to existing models, this model demonstrates a higher level of accuracy in predicting the flow patterns of mini-fluidized beds, particularly those with pronounced wall effect. This research has laid a foundation for the design, scale-up and industrial application of mini-fluidized bed reactors.