- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

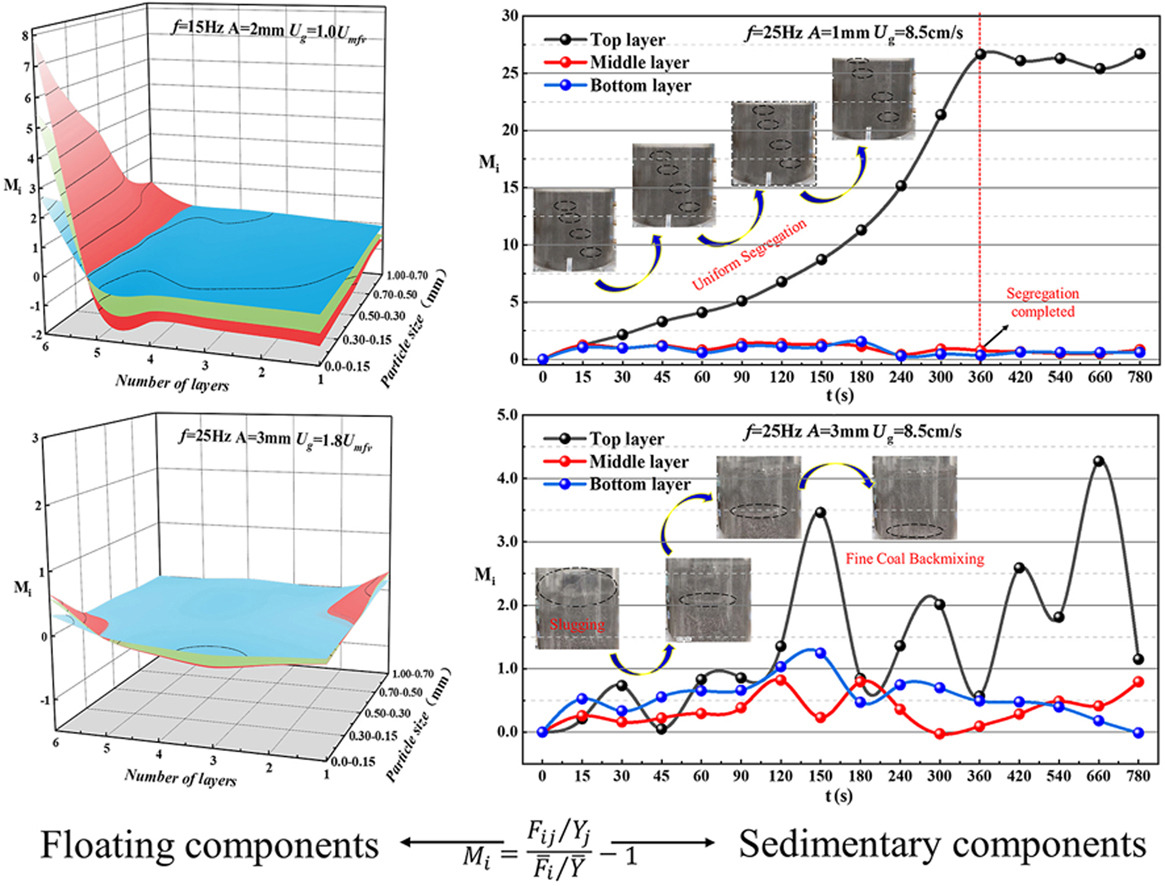

• The 0–0.5 mm fine coal is entrained by fine bubbles and separated at a uniform speed in a stable fluidization environment.

• Compatibility between fine coal and magnetite powder increases with increase of particle size of fine coal.

• Longitudinal density segregation and instantaneous density fluctuation after fluidization of binary dense medium are competitive.

This study investigates the impact of mixing 0–1 mm fine coal with 0.15–0.3 mm magnetite powder to form a binary dense medium. The aim is to examine how the 0–1 mm fine coal influences the stability of vibration separation in a fluidized bed and to achieve steady-state control of vibration fluidization. The vibration segregation behaviour of the binary dense medium under varying fine coal contents is analyzed in this work. The study discovers that the primary contributor to segregation is coal particles smaller than 0.5 mm. As the proportion of fine coal increases, upward movement becomes more pronounced, especially for particles smaller than 0.15 mm, where the upward segregation is most noticeable, with a peak mixing index of 8.06. The study confirms that the larger the particle size of fine coal, the higher the content limit for mixing with magnetite powder. According to studies on the process of fine coal segregation, coal particles larger than 0.5 mm move with the magnetite powder, and the mixing index remains below 3. Coal particles smaller than 0.5 mm fine coal will separate at a uniform speed in a stable environment produced by low vibration energy, with the top-level mixing index remaining constant at 26 after 6 min. Additionally, the study also examines how the fluidization of vibration separation is influenced by the segregation of 0–1 mm fine coal. The evidence shows that longitudinal density segregation within the binary dense medium competes with instantaneous density fluctuation. The longitudinal density distribution of the binary dense medium was found to be nearly uniform when the frequency was set to 25 Hz, amplitude to 2 mm, and upward gas velocity to 1.4 times the minimum fluidization velocity. The density fluctuation was found to be between 0 and 0.1 g/cm3. The best separation effect was achieved with fine coal particles ranging from 6 to 1 mm in size under these conditions.