- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

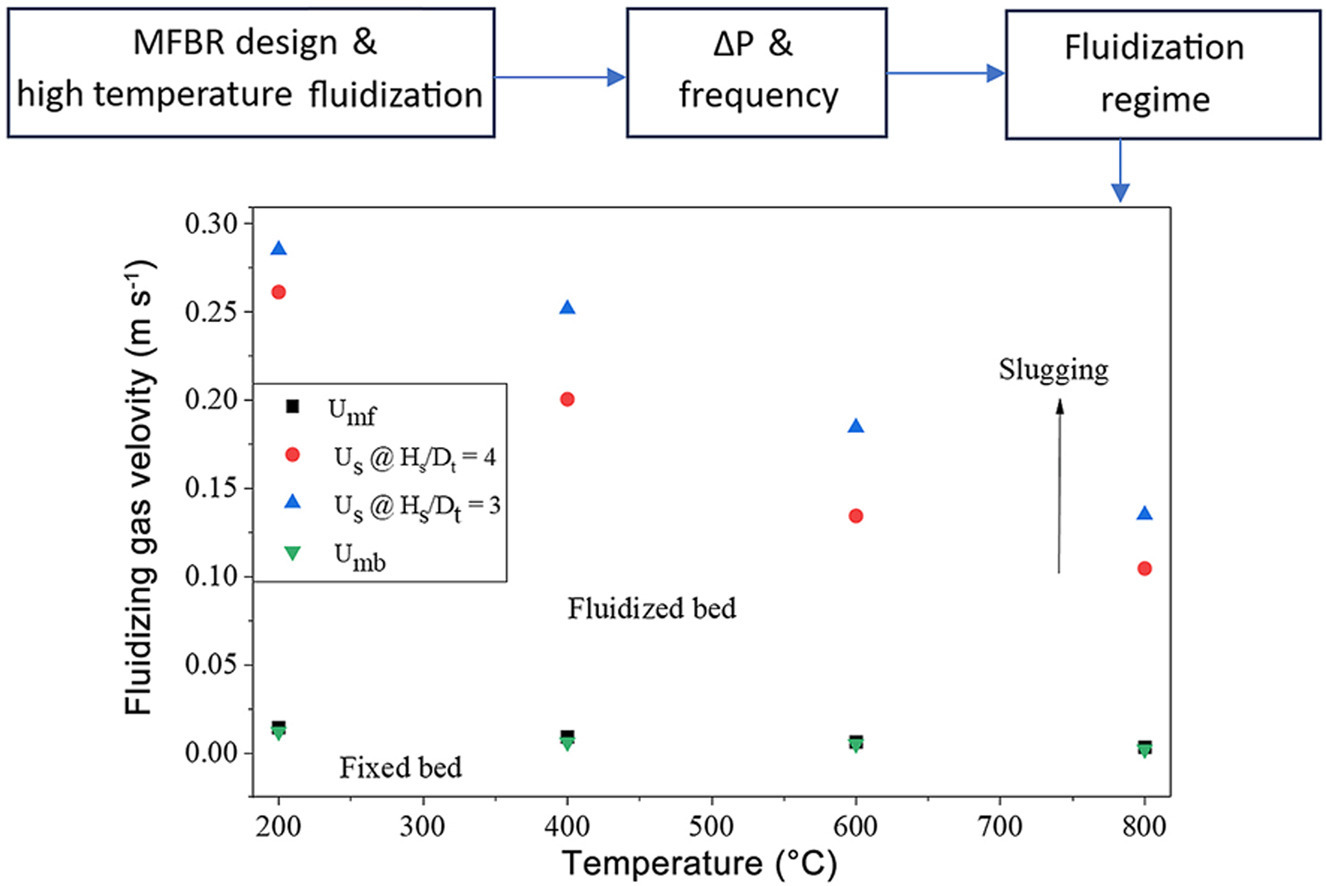

• Dominant frequency reduces as the operating temperature increases.

• Particle-bed wall effect on fluidization behavior increases at elevated temperatures.

• Inter particle forces dominate wall effects with increasing temperature.

• Structural changes in particles with temperature significantly alter bubble dynamics.

• Slugging is bigger issue for high temperatures in micro fluidized bed reactors.

Micro fluidized bed reactors (MFBRs) operating at high temperatures hold great potential for finding suitable conditions for kinetic screening experiments for CO2 capture sorbents. Additionally, high temperature hydrodynamics study using MFBRs prior to kinetics analysis could enable the acquisition of realistic and intrinsic kinetic data in transport phenomena-induced processes but the existence of wall effects could negatively impact quality of fluidization and cause delayed fluidization even though it may aid reaction kinetics. High temperature hydrodynamic studies in MFBRs remains relatively unexplored despite its enormous potential. In this work, we designed a high temperature MFBR system to perform detailed hydrodynamic experiments using pressure drop characterization approach to analyze the effect of temperature and bed-wall friction on various fluidization regimes with Geldart B limestone sorbents by controlling temperature with portable induction heater. Results show that minimum fluidization velocity decreases with increasing temperature for both Nauli and Oterpkolu limestones due to increased Van der Waals forces and the cohesiveness between particles at elevated temperature; with the gradient of the decrease in minimum fluidization velocity being steeper between ambient temperature and 400 °C compared to the drop between 400 and 800 °C. At 600 °C, bubbles started appearing at air flow rate of (0.065 m/s) but bubbling started at 0.142 m/s and 400 °C. Frequency spectra revealed that the superficial gas velocity at which a dominant frequency is attained (when slugging fluidization begins) reduces as the operating temperature increases. Additionally, bed pressure drop overshoot per volume of particle bed increases with increasing operating temperature.