- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

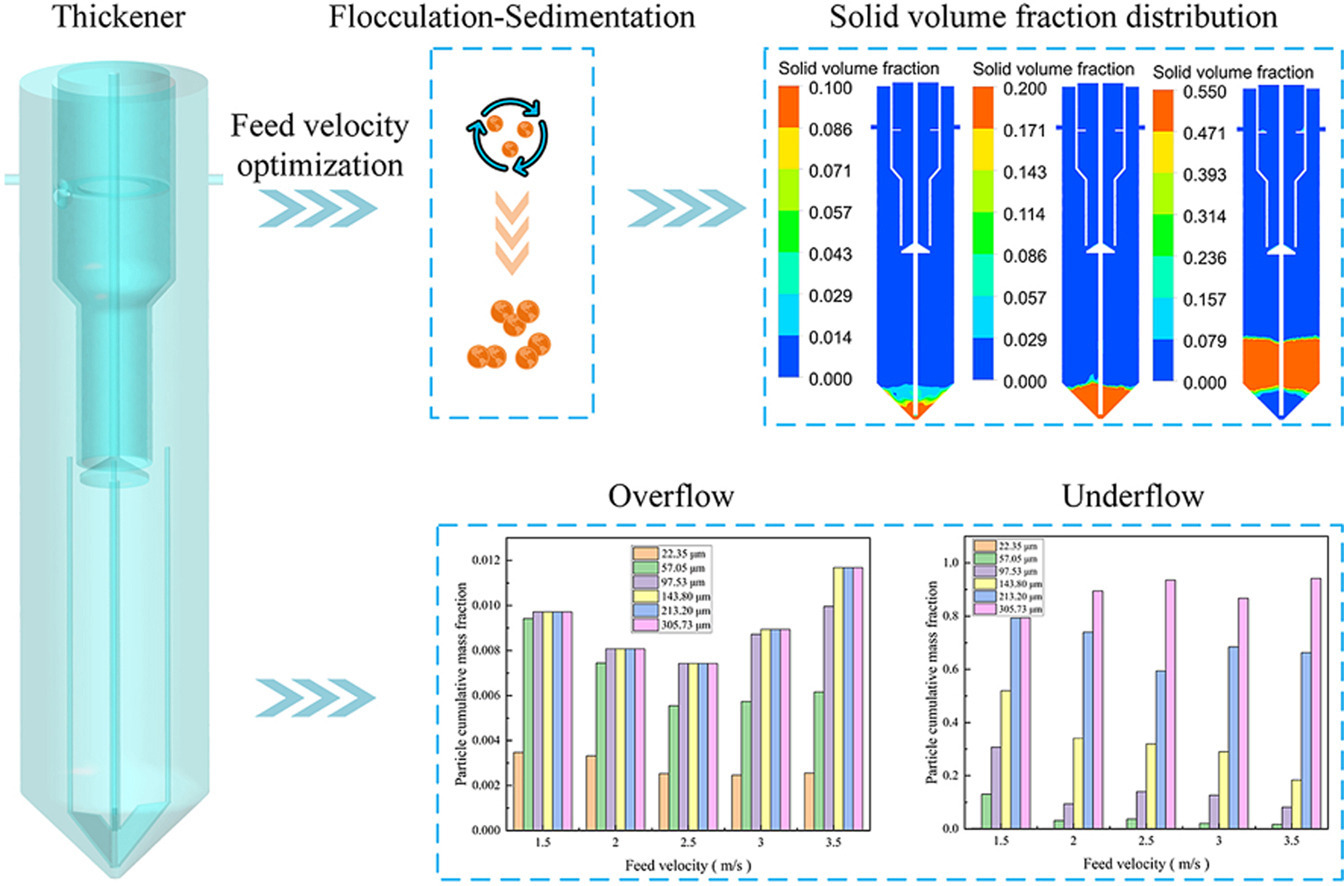

• A novel CFD-PBM-KTGF framework was proposed to simulate flocculation-sedimentation process by steps.

• A visualization analysis of particle behavior inside the thickener was conducted.

• Effects of turbulent characteristics on particle aggregation and floc breakage are systematically analyzed.

• Thickening efficiency was improved through the feeding parameters intensification.

This study employed coupled the Computational Fluid Dynamics-Population Balance Model (CFD-PBM) framework and Kinetic Theory of Granular Flow (KTGF) to investigate the flocculation and sedimentation dynamics of polymodal tailings particles in a lab-scale gravity thickener. The Euler-Euler multiphase model and RNG k-ε turbulence model are integrated to simulate solid-liquid interactions and turbulent flow characteristics, while flocculation kinetics, including aggregation and breakage mechanisms, are incorporated to quantify particle size evolution. The influence of feed velocity on flow field characteristics and particle flocculation-sedimentation efficiency was analyzed through visualization. The results indicated that the turbulent energy distribution is highly sensitive to the feed velocity. The optimal velocity range (2.0–2.5 m/s) promotes a balanced aggregation-breakage dynamics of particles, stabilizing the formation of larger flocs and enhancing sedimentation. Excessively high feed velocities (>3.0 m/s) induce stronger turbulence, reducing floc size and impairing sedimentation efficiency. Spatial analysis reveals that fine particles (<50 μm) are widely dispersed, while large flocs (>100 μm) dominate the underflow solid concentration. The impact of floc size and density on sedimentation was also examined. This study identifies a critical threshold for feed velocity to optimize thickener performance, providing a theoretical basis for process intensification in industrial thickeners.